Liquid Forging Overview

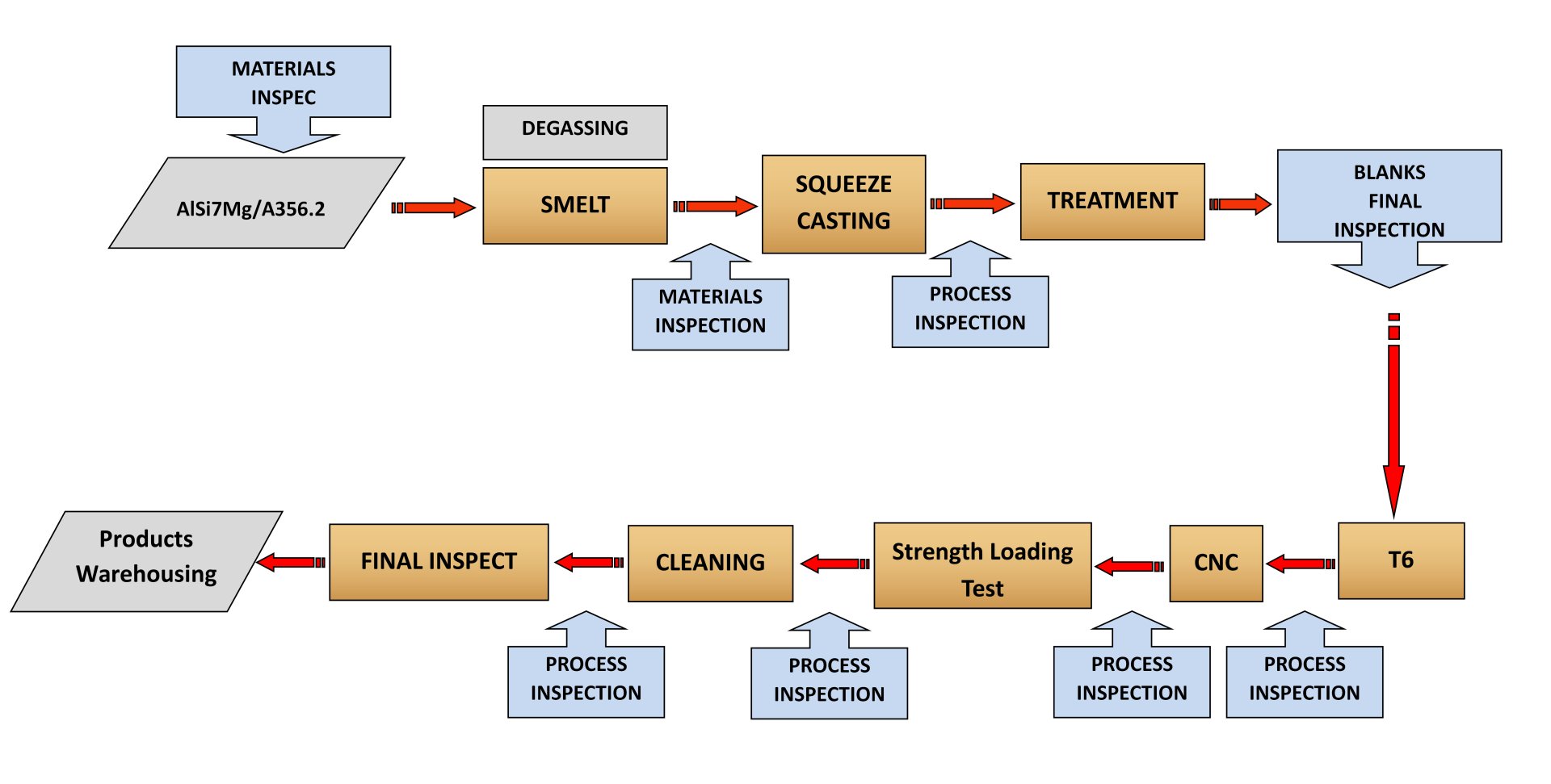

Liquid Forging(Squeeze casting) is a process by which molten metal solidifies under pressure within closed dies positioned between the plates of a hydraulic press.The applied pressure and instant contact of the molten metal with the die surface produce a rapid heat transfer condition that yields a pore-free fine-grain casting with mechanical properties approaching those of a wrought product. The squeeze casting process is easily automated to produce near-net to net shape high-quality components.

The material: A356; A356.2, AlSi9Mg; AlSi9Cu3, 319S, Al-Ti-Alloy; ZL104,ect.

Sizes avaliable: 3mm~10mm wall thickness;

Weight: 100g~10kg noramlly

Largest length: 400mm. Some narrow sizes can be longer and thicker.

Note: above is for general situation and finally must be according to drawings.